This blog post will walk you through a complete project-based approach using Odoo v18, ensuring you optimize resources, track costs accurately, and enhance efficiency at every stage.

The Key Phases of a Manufacturing Project in Odoo

Sales

Customer initiates contact and the Sales Team will give an initial Quote

Project Creation

Create a Job and it's budget

Purchasing

Raise RFQs from your vendors and enter expected receipt dates

Delivery & Installation

Schedule delivery and arrange Installation

Scheduling & Manufacturing

Schedule your Fabrication and assembly for each of the sub-assemblies

Reporting

Analyse the margins, actuals vs budgeted and use the learnings for your next big order!

A typical high-value manufacturing project ($50K to $500K) requires careful planning, budget control, and execution. Below is a step-by-step breakdown of how Odoo v18 supports each stage:

1. CRM & Sales: Initiating the Job

Every project begins with a customer inquiry. The salesperson enters job details into Odoo's CRM module and generates an initial quote.

- Either create a Quotations directly in the Sales system, or you have a holding Kanban Board with all your opportunities in one sheet.

- Salespeople and designers can allocate non-billable time to feasibility studies using timesheets.

- If the client expresses interest, revisions can be made, and a formal proposal is sent.

- Odoo has the ability to generate a Quote from a template structure where you design your PDF and link each aspect of your Sale Order to the dynamically generated quote. Here's a video about the process.

2. Project Creation: Structuring the Work

Once the customer approves the quote and sends a Purchase Order (PO), a Project is created in Odoo.

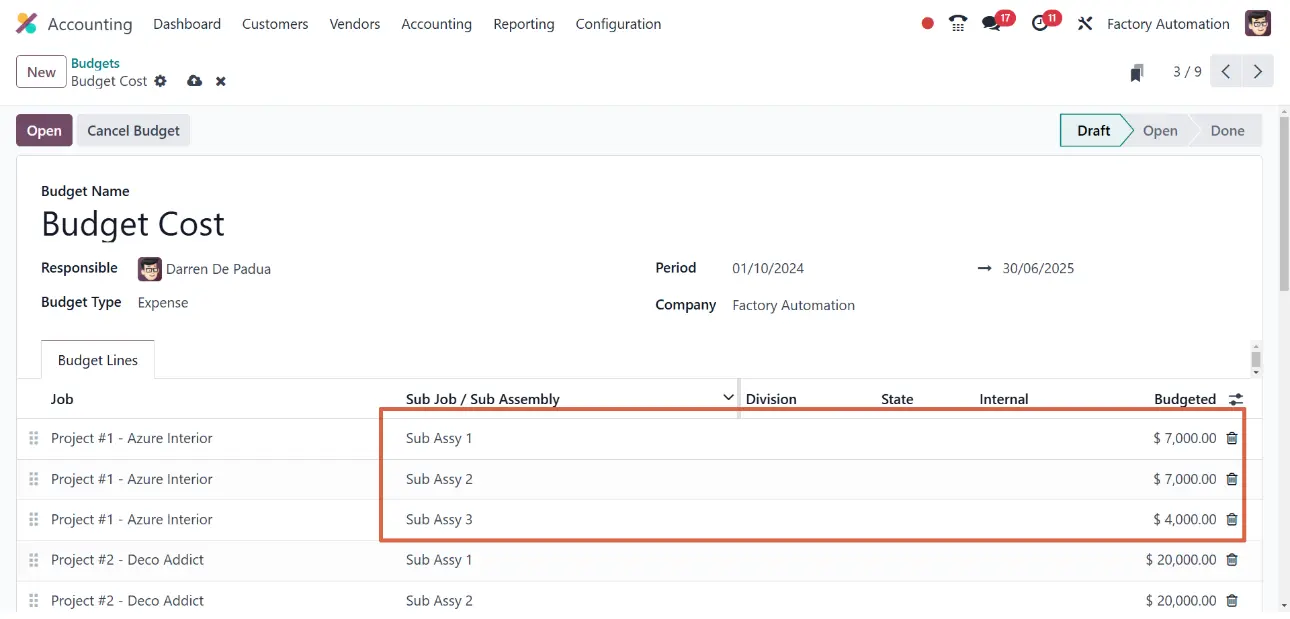

- Budgets are established using Analytical Accounting, allowing businesses to track revenue and expenses in a structured manner. So the key aspects at this stage will be to:

- Create a Project

- Create it's Analytic Plans and Analytic Accounts.

- And then allocate budgets

- Costs can be divided into "buckets" for either each sub-assembly or for the operation (such as costs planned for Engineering, Drawing, Fabrication, Assembly, etc), ensuring accurate financial planning and resource allocation.

- You need to use the Sub-Plan feature in Odoo for this.

- Each budget can also be set with predefined cost categories such as materials, labour, subcontracting, and overheads.

Odoo's budget management tools allow for real-time tracking of expenses, ensuring manufacturers stay within their financial limits.

- Budget adjustments and variations can also be entered and analysed, enabling manufacturers to adapt to project changes without losing financial visibility.

- At this stage any variations can be communicated to the client and then possibly increase the value of the sale.

- Approval workflows can be integrated into budget management, ensuring that financial decisions align with overall project goals.

3. Purchase & Inventory Management: Procuring Materials

With budgets set, the next step is to acquire materials:

- Purchase Orders (POs) are raised based on required materials. On the purchase order you'll need to "tag" the purchase to a Project / Job or possibly a Sub-Assembly / Operation.

- Inventory Management ensures stock levels are optimized, preventing delays.

- Materials are allocated for specific sub-assemblies.

4. Manufacturing Scheduling: Planning Production

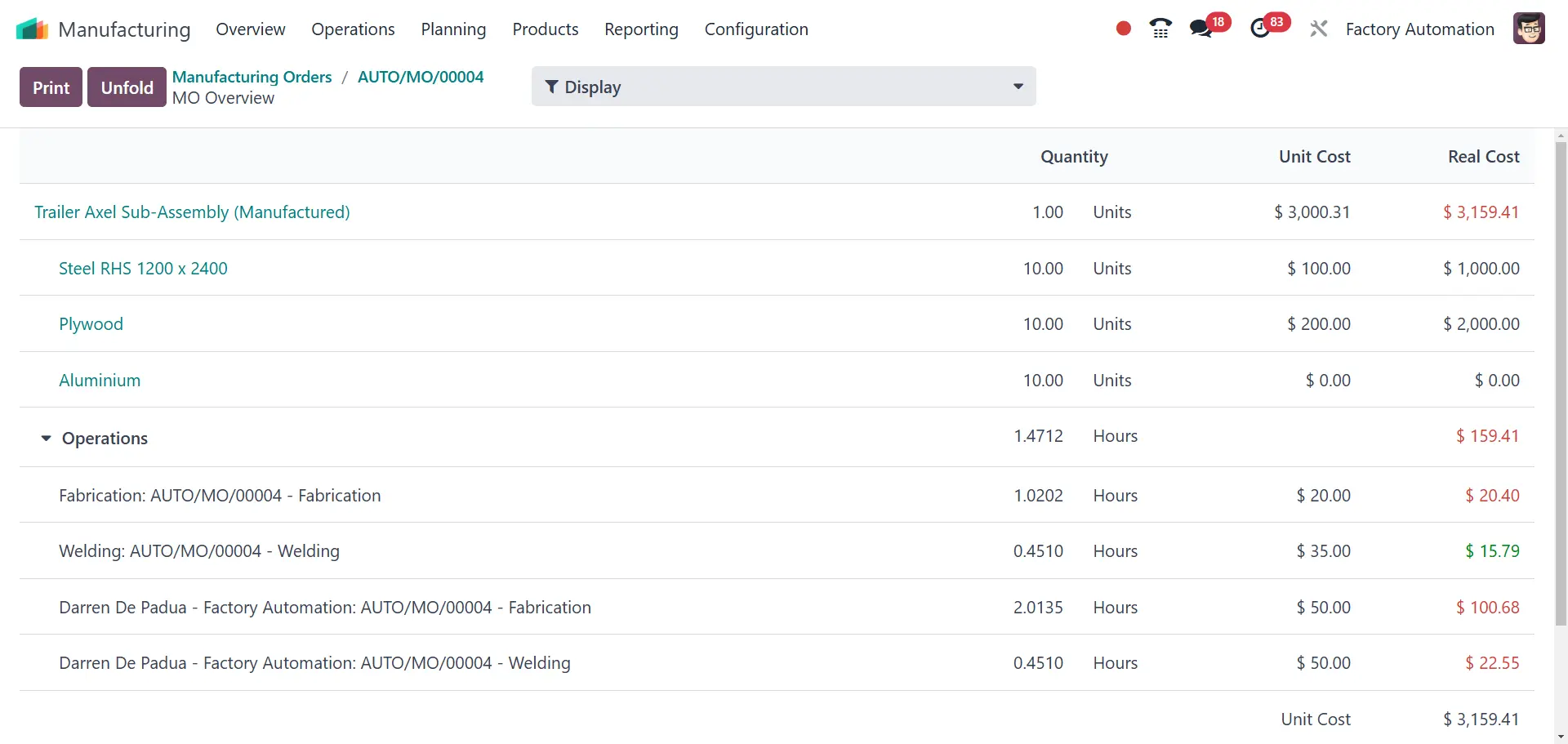

Production is broken down into sub-assembly production orders, ensuring an organized workflow.

- The MRP module helps manufacturers plan capacity and assign work to production teams.

- Scheduling tools assist in optimizing machine and labour allocation.

5. MES (Manufacturing Execution System): Real-time Tracking

Using the Shop Floor app, manufacturers can:

- Provide real-time work instructions to operators.

- Track actual production times to measure efficiency.

Log any delays or issues affecting production.

6. Delivery & Invoicing: Completing the Project

Once manufacturing is complete:

- The Inventory and Warehouse Management module ensures timely delivery to the customer.

- A final invoice is generated, considering all materials and labour costs.

The Field Service could be used if you have an active Installation Team.

7. Reporting & Budget Analysis: Refining Future Jobs

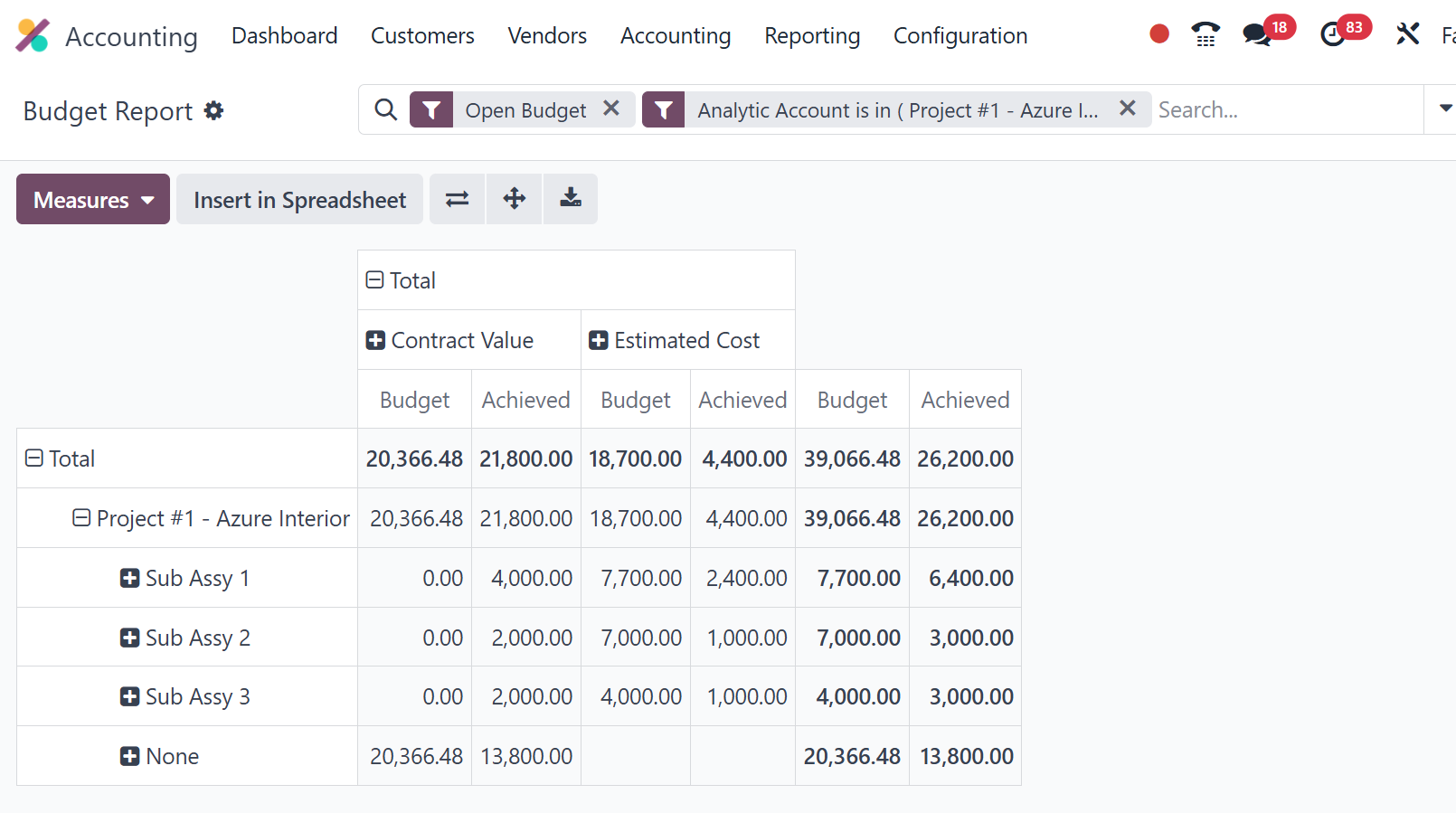

One of the most valuable aspects of Odoo is its reporting and analytics capabilities:

- Compare planned vs. actual costs since all your financial transactions are now tagged with the Job and it's Sub-job (Sub-assembly or Operation).

- Analyse labour costs recorded in the MES.

- Use these recorded times to Analyse Actual Vs Estimated times.

- Use these insights to improve pricing and quoting accuracy for future jobs.

Why Choose WMSSoft?

When selecting an Odoo partner for your manufacturing business, WMSSoft stands out because:

- Deep Understanding of Australian Manufacturing & Distribution: We specialize in local industry needs, ensuring compliance and best practices.

- Custom Odoo Enhancements: We go beyond standard Odoo features to provide:

- Simplified Budget Entry: Faster and more intuitive budget setup.

- Australian Accounting Integration: Seamless financial compliance.

- Work-in-Progress (WIP) Management: Improved tracking for ongoing projects.

- ...any many more.

Conclusion

Implementing Odoo v18 for projects based manufacturing can significantly improve efficiency, cost tracking, and project execution. Whether you're starting your ERP journey or looking to optimize your current system, WMSSoft can help tailor Odoo to your specific business needs.

Ready to streamline your manufacturing operations? Contact WMSSoft today and take the first step towards a smarter ERP solution!